ミノムシ繊維について

About the Eecology of Bagworms

Bagworm is a general term for the larvae of moths in the Psychidae family of the Lepidoptera order. They usually hide in spindle-shaped or cylindrical nests (bags) made of leaves or twigs bound with silk, and are known to live with the bag throughout their entire larval stage, moving around with the bag even when feeding. Broadly distributed in all zoogeographic regions outside the poles and deserts, about 1,000 bagworm species exist globally, with Japan being home to around 50 species. Eumeta variegata is a typical species living in Japan.

Soon after emerging, the bagworm makes a bag in which it spends its entire life. When it moves, it lifts its abdomen (which is covered by the bag) off the ground and then moves such that it is upside down. It looks like a small, pointed hat is walking along, a cuteness straight out of a picture book. The larvae grow from summer to fall, and the bag’s top potion is attached to a twig through winter. In spring, the larva pupates inside its bag and emerges in early summer as an adult. When an adult male emerges from its bag, it flies around like other moths. Adult females, on the other hand, have a larva-like form that lacks wings, legs, antennae, and eyes – they remain inside the bag, mating and laying eggs until they die.

A distinctive feature of bagworms is that for many of their species, the morphology of adult males and females greatly differs.

Why We Chose Bagworms

Silk thread is a natural fiber with industrial applications. The thread has a single fiber that’s spun by silkworms, and, during the silkworm’s lifecycle (around 2 months), a cocoon is produced in a brief period of 2 to 3 days, just before the silkworm pupates. To use silk thread as fiber, the pupa within each cocoon must be killed. In contrast, bagworms spin fiber immediately after birth and continue to spin it throughout their larval stage, meaning that they can be bred to produce fiber.

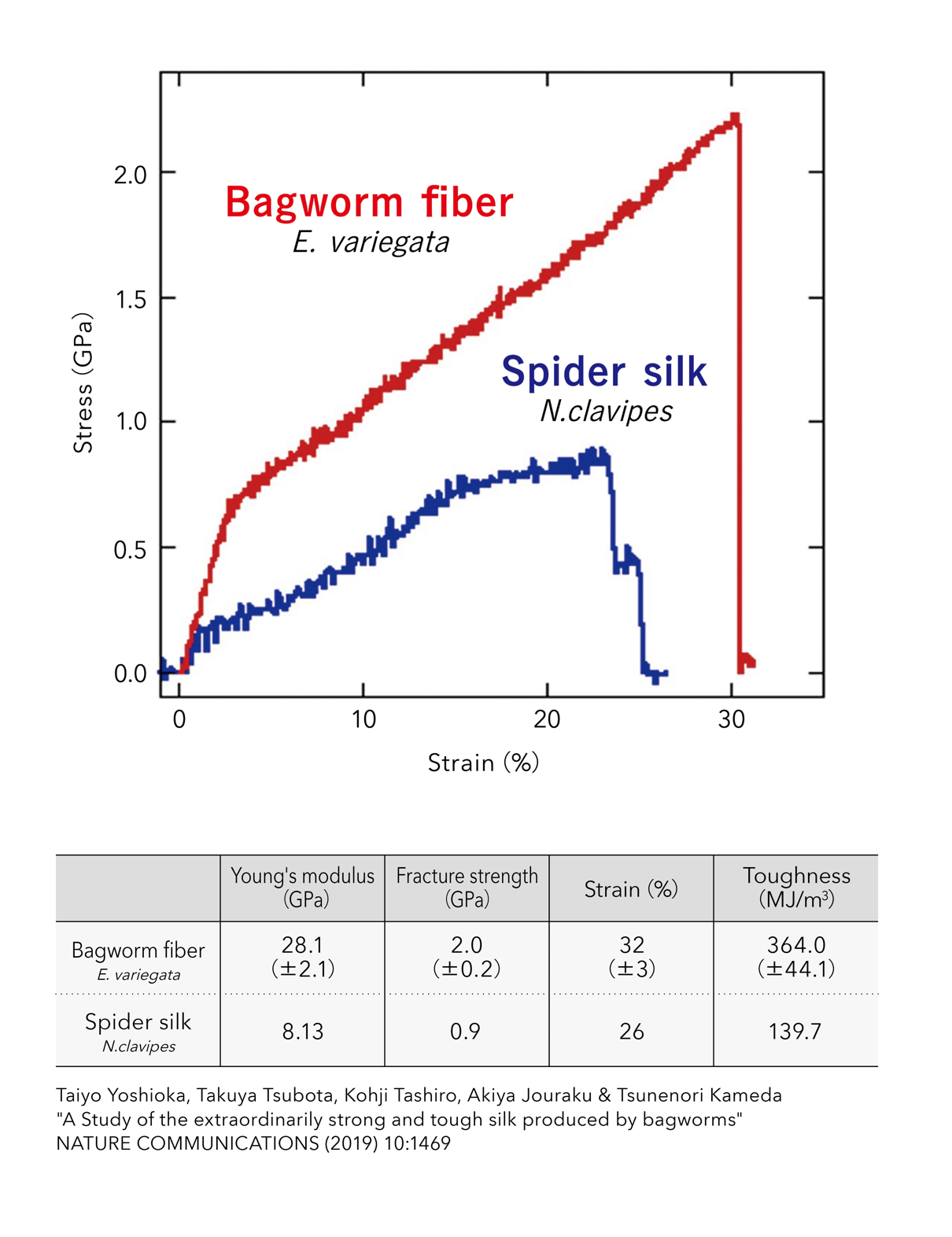

Moreover, when we commenced using bagworm fiber—which derives from the Eumeta variegata larvae—for industrial applications, we found that its elastic modulus, breaking strength, and toughness exceeded those of spider silk, which was said to be the strongest natural fiber at the time. This convinced us that bagworms, which can continually spin strong fiber, have enormous value.

(For Industrial Use)

Wild bagworms have a life cycle whereby a generation lasts one year. They live while being affected by the seasons and their natural habitat where many natural enemies exist.

Since spring 2017, in order to use bagworm fiber for industrial purposes, we have researched artificial rearing together with the National Agriculture and Food Research Organization.

We can now efficiently and quickly rear large amounts of bagworms indoors. Moreover, in order to achieve a more sustainable manufacturing process, we’re developing methods aimed at minimizing the burden placed on both bagworms and the environment.

Natural Fibers with Superlative Physical Properties

Of all natural fibers, bagworm fiber has the highest degree of (1) elastic modulus, (2) breaking strength, and (3) toughness.

(1) Elastic Modulus

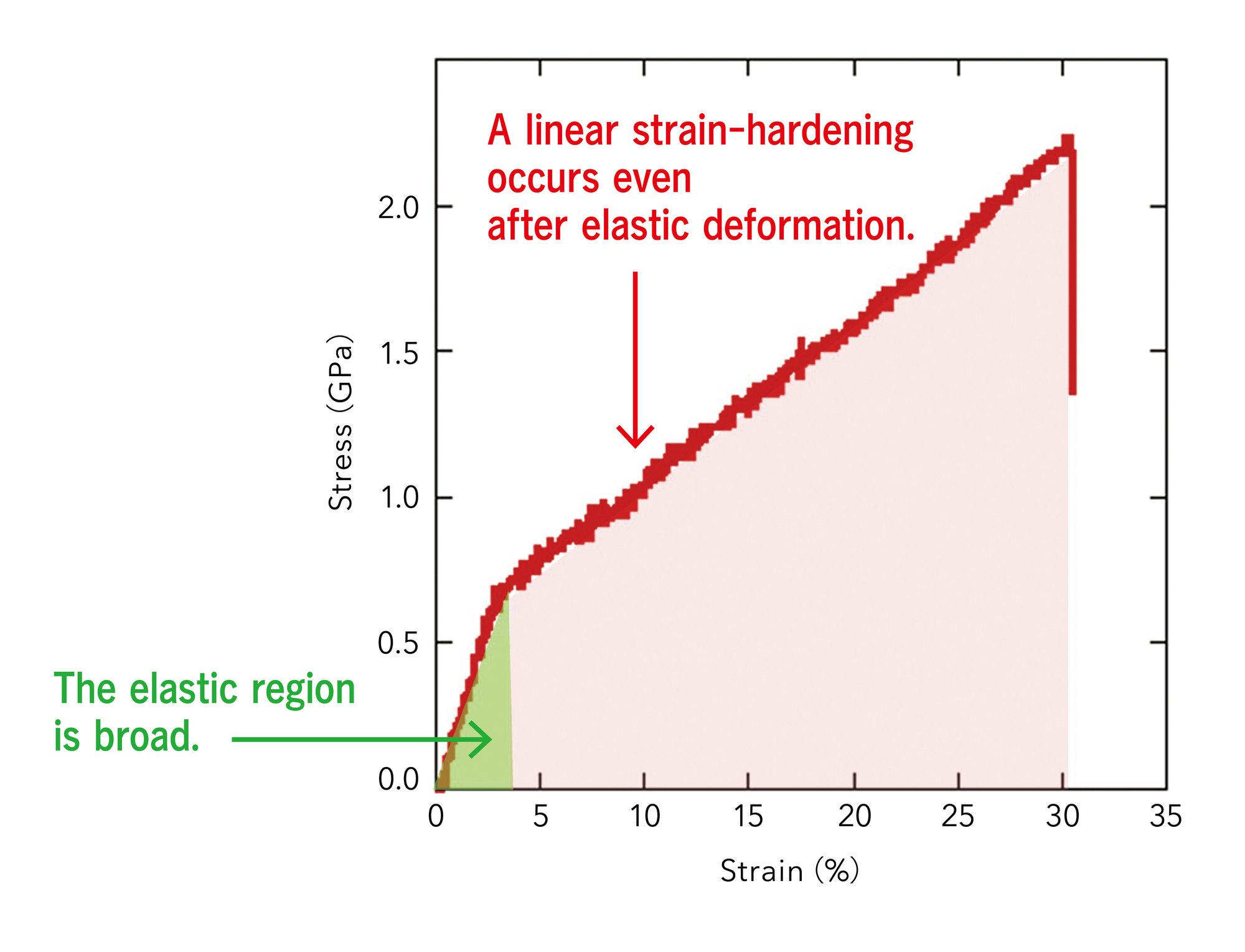

This is a physical property that indicates how resistant a fiber is to deformation. It is defined as the slope (stress/strain) of the initial portion of its stress-strain curve, and it corresponds to the spring constant. Also known as Young's modulus, the higher the value, the harder the fiber.

(2) Breaking Strength

The value (stress) is obtained by dividing the tensile load or force required to break the fiber by the original cross-sectional area. The higher the value, the stronger the fiber.

(3) Toughness

This is the integral value of the stress-strain curve. It corresponds to the energy absorbed up until when the fiber breaks. It is used as an index of toughness, and the higher the value, the more steadfast and durable the fiber is. High breaking strength and high toughness have different meanings: Toughness indicates how much energy can be absorbed as the material deforms, so if the material has rubber-like properties (weak but highly stretchable), the value will be high.

Special Properties Perfect for Structural Materials

Structural materials generally require both strength and toughness. Bagworm fiber has a well-balanced combination of high elasticity, high strength, high elongation, and high toughness. Moreover, even in bagworm fiber’s plastic deformation area, stress increases linearly with tension. Given these distinctive features, bagworm fiber is a promising candidate to be a structural material and is expected to be used as a new industrial fiber.

The Structure of Bagworm Fiber

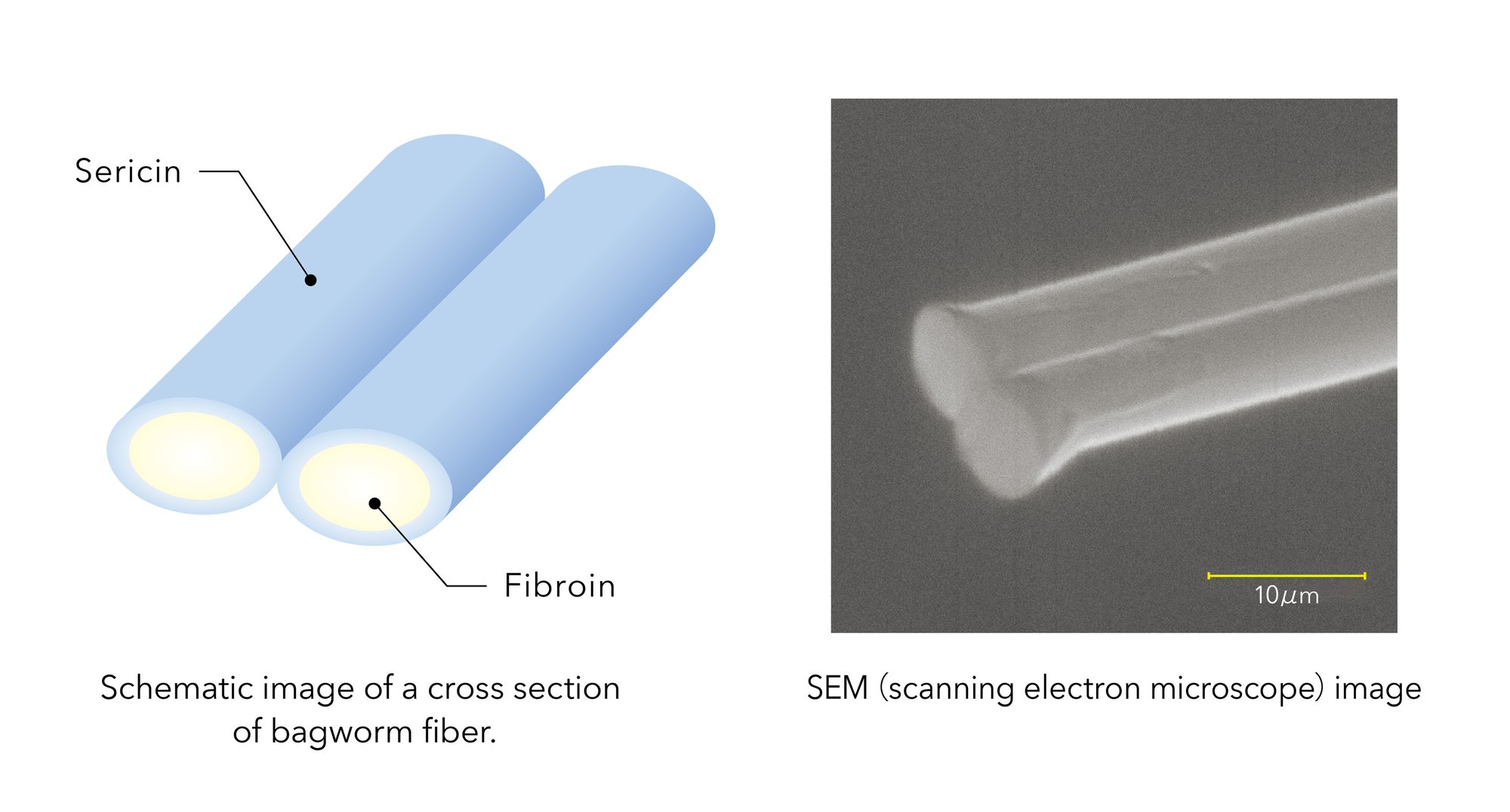

Akin to silkworm silk, bagworm fiber is made up of two proteins: fibroin and sericin. On bagworm fiber’s inside is fibroin, which is covered by sericin on the outside.

Silkworm silk is used to make clothing and other products through a process called scouring, which removes the sericin. It’s now clear that bagworm fiber’s sericin can be removed by scouring the fiber. And with this technology, we are researching bagworm fiber’s fibroin protein.

Environmental Problems Faced Worldwide

Petroleum-derived plastic products such as polyester, nylon, acrylic, and polyurethane have superb strength and durability that can compensate for the drawbacks of natural materials. These products have enriched our lives.

However, they take a long time to decompose, and once they’ve broken down, their fine particles may harm humans and other living organisms. Moreover, fossil fuels such as petroleum and natural gas are needed to produce plastic products, and concerns exist about CO2 emissions increasing during production and waste disposal.

This plastic problem is a major issue that needs addressing through cooperation between countries worldwide, and demand is robust for materials with low environmental impact.

Eco-Friendly Thanks to its Natural Properties

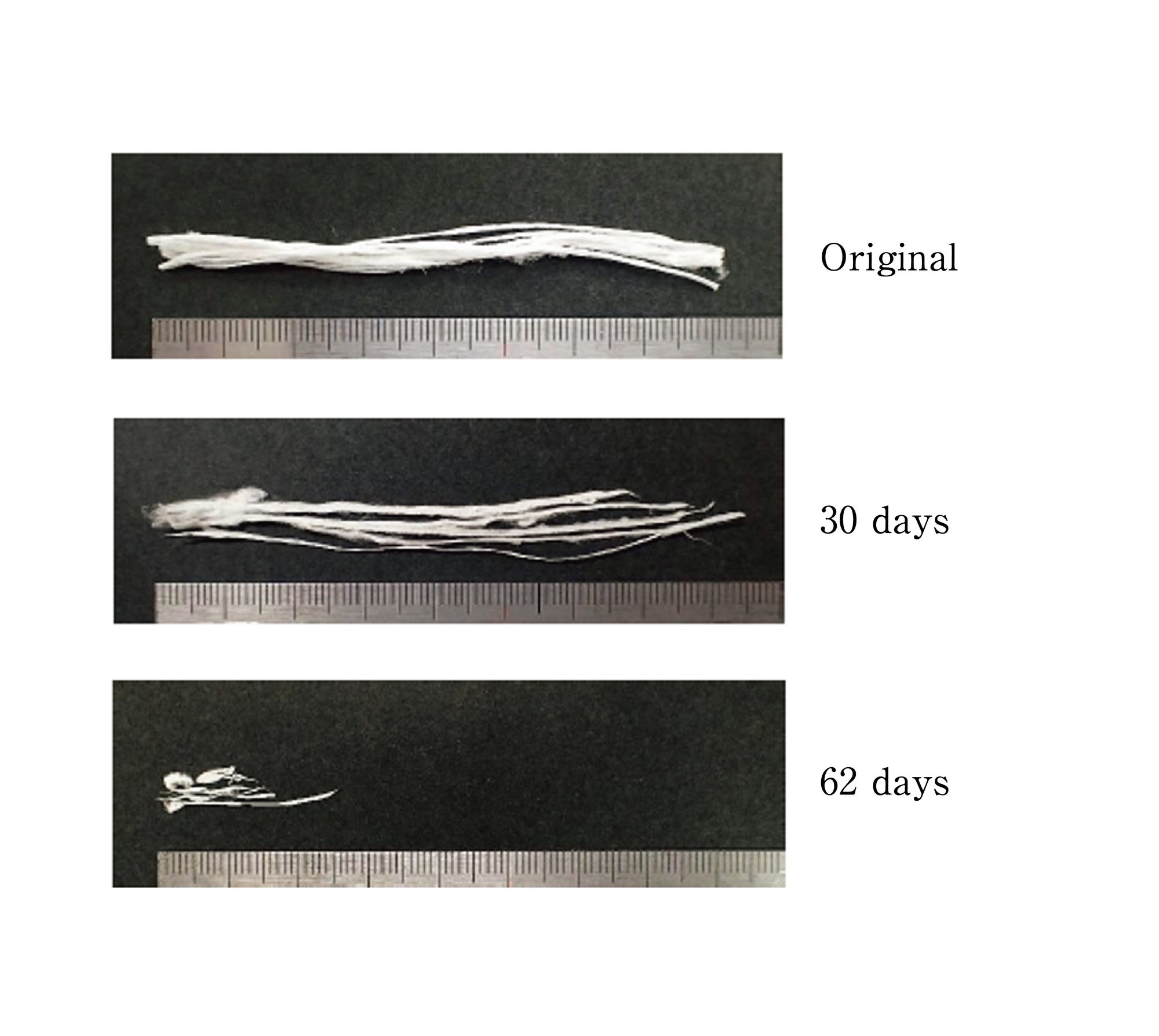

Bagworm fiber has outstanding toughness and is composed only of naturally occurring amino acids. In a thread-disintegration test conducted in a marine setting, we confirmed that most of the thread had disintegrated after two months and had completely done so after three.

MINOLON's Approach to Biodegradation

Even plastic that has broken down into particles invisible to the naked eye may adversely affect ecosystems, so there are calls for materials that decompose into water and carbon dioxide as quickly as possible after breaking down.

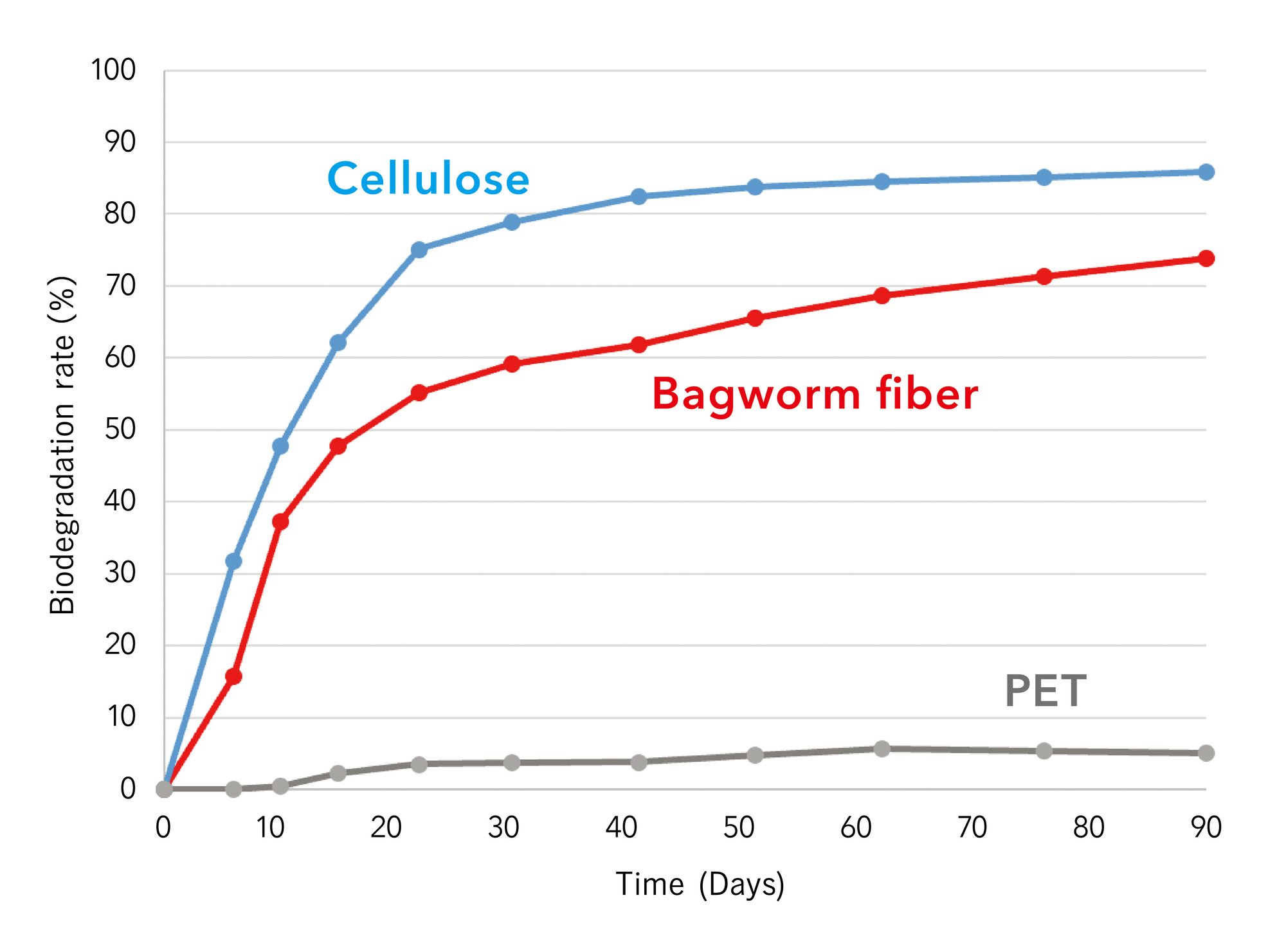

We have confirmed that bagworm fiber decomposes in marine environments. A 90-day evaluation showed bagworm fiber had biodegraded more than PET (polyethylene terephthalate) and biodegrades in a manner similar to cellulose.